The factory that saved thousands of Shekels in fines and cut chemical usage by over 70% thanks to the implementation of a professional upgrade and connection to the Greenfield Eco network 📈

- Roee Shifron

- Oct 8, 2025

- 4 min read

"It's clear to us today that this was the right move: we are enjoying operational savings, a cleaner working environment, and a significant contribution to pollution reduction."

Dealing with environmental regulation and high operating costs is a significant challenge for many factories. An in-depth analysis of the wastewater treatment processes at a factory in Northern Israel revealed tremendous potential for improvement.

The factory faced complex challenges in its wastewater treatment system. The old system, which operated with a fixed dosage, required a dosage capable of handling fluctuating flow rates and contaminant concentrations. This led to increased chemical consumption, environmental standard violations, and high operating costs.

The factory had been presented with proposals for expensive new treatment facilities and costly upgrades.

"The factory, which had previously received numerous proposals for various (new) facilities, decided to take an innovative and creative approach. Instead of committing to a large, cumbersome project, it gave Greenfield Eco the opportunity to prove that there was a better way.

Thanks to creative thinking combined with years of knowledge and experience, Greenfield Eco began a simple, yet smart and effective upgrade at the end of 2023. This included connecting the factory's facility to the Greenfield Eco network for continuous monitoring and operational guidance from Greenfield Eco's national control center. The factory underwent a dramatic transformation—successfully achieving a significant reduction in contaminant concentrations, saving tens of percent in chemical costs, and reaching full compliance with the standard.

The Challenge: An Inefficient System and Increased Consumption

Before the upgrade, the factory's system operated without precise control and without continuous flow measurement, as the gravity-fed pipe did not allow for it. Without remote control capabilities, the addition of chemicals (such as coagulants) was done at a fixed dosage that did not account for the incoming flow rate. This situation created several challenges:

Overconsumption and Repeated Violations: The lack of coordination between the different chemical dosages—the base and the acid counteracted each other in an uncoordinated manner, leading to an increased volume of sludge and excessive chemical use. To ensure compliance with the standard, even during high flow rates, the factory was forced to constantly set the chemical dosage to the maximum level. Consequently, the system frequently ran with an expensive chemical surplus, escalating operating expenses which included fines for violations, high chemical costs, and an increased amount of sludge.

After consulting with environmental advisor Eldad Sharony, the factory decided to adopt an innovative and creative approach. Instead of committing to a large, cumbersome project, they gave Greenfield Eco the opportunity to prove that there was a better way.

"We immediately understood that we didn't need to commit to expensive and cumbersome projects to achieve better results. We saw the immense potential in the existing system and acted accordingly. The result? Full compliance with standards, dramatic cost savings, and a reduction of tens of percent in chemical use." — Roee Shifron, Professional Manager at Greenfield Eco

The Solution: A Professional, Efficient Upgrade of the Existing Facility

Including Control, Precision, and Training

Greenfield Eco's professional team upgraded the existing facility with an innovative, continuous

treatment system by:

Smart pH Control: Installing an advanced control system with more accurate pH correction capabilities.

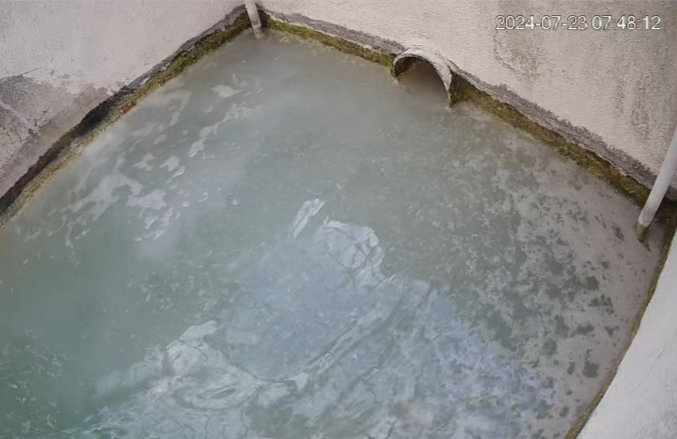

National Control Room Connection: The factory was connected to one of the company's flagship services—Greenfield Eco's National Control Room, which monitors the quality of treatment using cameras, connects to the controller, and receives 24/7 alerts. This provides continuous remote control over dosages and real-time response to alerts. Thus, a professional accompanies the factory around the clock, not just through periodic visits, without incurring high costs.

On-site Process Support: Providing on-site procedural guidance to optimize chemical use and processes for maintaining optimal treatment.

Flow-Based Dosing: Implementing an innovative system that precisely controls the amount of incoming chemicals (coagulants) based on the incoming flow rate to the facility. This improved the chemical process, reduced chemical dosages, and yielded excellent results in separating solids into sludge and clear effluent (filtrate).

Professional Training: As part of the service the company provides, the factory's operating team underwent thorough training on the operation, maintenance, and cleaning of the upgraded facility.

The Greenfield Eco Network's Industrial Effluent Control System

The Results: A Data Turnaround and Savings

Dramatic Reduction in Chemical Consumption: The switch to precise dosing was immediately reflected in the data:

Acidic Chemical: Consumption of approximately 2,600 liters in January 2024 dropped to just 742 liters in March 2024, a decrease of over 70%.

Basic Chemical: Consumption of approximately 275 liters in January 2024 dropped to 193 liters in March 2024, a decrease of about 30%.

Before the upgrade:

After the upgrade:

Impressive Drop in Contaminant Concentrations (mg/liter): The following graph illustrates the continuous decline in the concentrations of the main pollutants from the moment the project began in late 2023 until today, and the shift to full compliance with standards:

Comparison of Contaminant Concentrations (mg/liter)

The story of the Kabiran factory proves that it is not always necessary to pursue grandiose and expensive solutions. A custom-engineered solution, derived from a deep understanding of the factory, its production processes, and its wastewater treatment, improves not only operational aspects and regulatory compliance but also the business's bottom line. The shift to full compliance with standards, alongside a dramatic reduction in chemical expenses—all without embarking on costly and prolonged projects—demonstrates Greenfield Eco's added value as a true partner for green and economic growth.

The Kabiran story proves: Sustainability and economic savings can go hand by hand.

Interested in discovering if your facility can achieve a comparable transformation? Get in touch with us today!

Connect with us! Follow us on Facebook and LinkedIn (Greenfield eco). Call 046829999 or message us on WhatsApp at 0559555874.

Comments